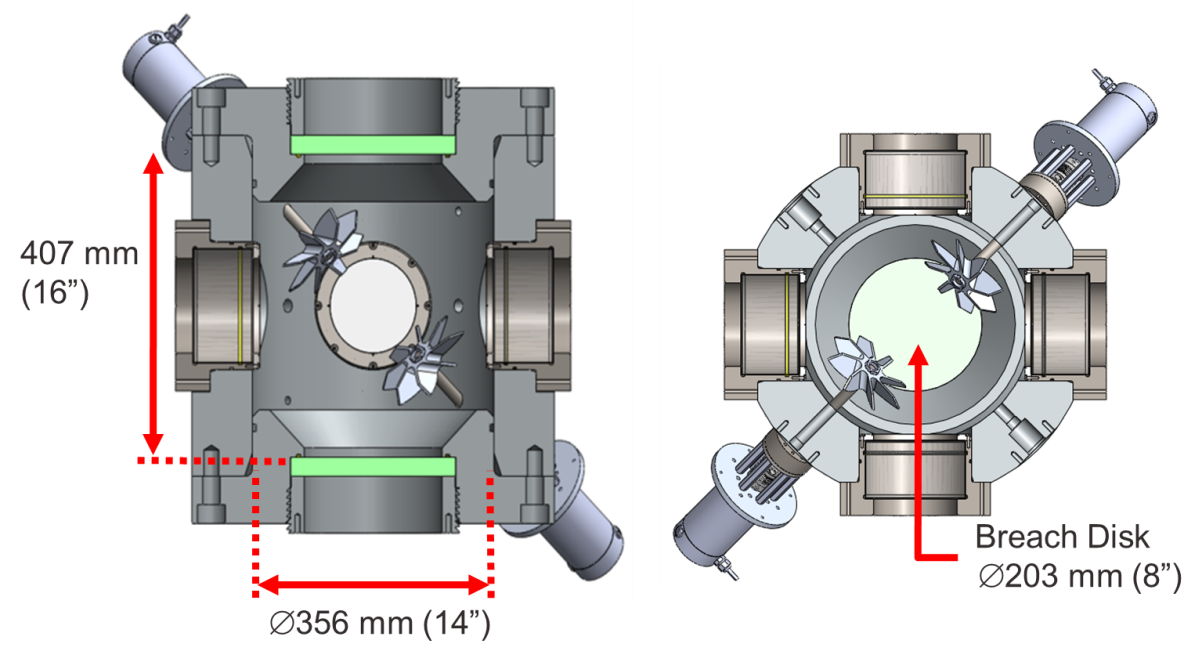

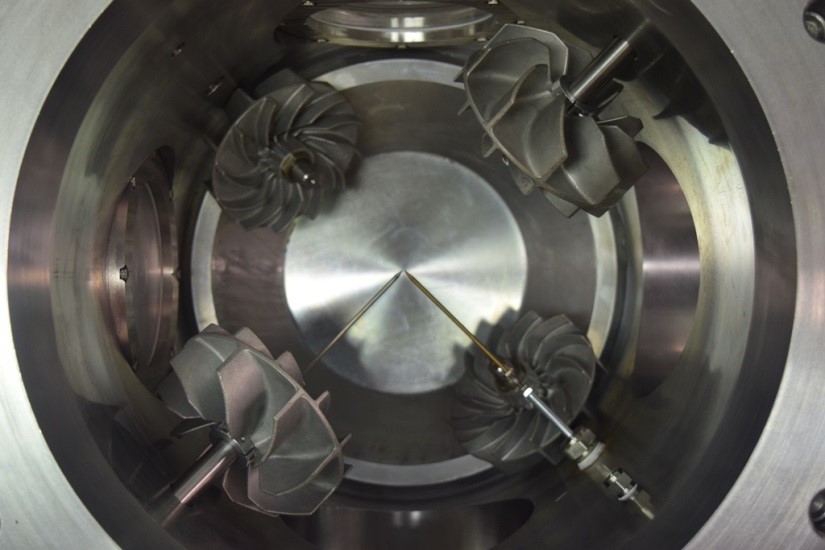

For the study of laminar and turbulent flames, the Petersen Group has designed and constructed a fan-stirred flame vessel known as the Turbulent Flame Speed Vessel (TFSV). TFSV is a constant-volume, stainless steel cylindrical vessel with four optical ports, each installed with 3.5 inch (8.9 cm) thick, 5 inch (12.7 cm) diameter fused quartz windows to provide two perpendicular axes of optical access. The internal volume of the TFSV is approximately cylindrical, with a volume of approximately 1950 cubic inches (32 liters). The internal dimensions of the TFSV are labeled in the figure below. The TFSV possesses four stirring fans positioned tetrahedrally with 5.75-inch (14.6-cm) diameter impellers to provide known turbulence intensities of up to 18.0 ft/s (5.5 m/s) when desired. The impellers are shown as installed in the TFSV in the figure below. Turbulence intensities are measured using laser Doppler velocimetry. The impellers are powered by DC motors capable of speeds up to 10000 rpm. The TFSV can also conduct laminar flame tests with the fans installed in the vessel.

Schematic of the TFSV, with internal dimensions shown.

Photo of the TFSV, looking inside from the top, with impellers and electrodes installed.

The TFSV was designed for initial (pre-combustion) conditions of up to 10 bar (145 psi) and 130°C (260°F), with appropriate factors of safety. The pressure condition is limited by the strength of the quartz windows of the vessel. In the vessel’s current unvented configuration, the TSFV is designed to withstand the full brunt of the test pressure, up to 1500 psi. The initial temperature condition is limited by the o-rings currently used to seal the vessel. The TFSV contains breach disks at both the top and bottom which can be replaced with rupture diaphragms for vented deflagration tests, which increases the initial pressure limit to 20 bar (290 psi).

The clear aperture of the windows allows optical measurements of flames of up to 5 inches (12.7 cm) in diameter, which corresponds to a burned-gas volume of approximately 3% of the total vessel volume. Perpendicular lines of sight through the windows provide TFSV with compatibility with many optical diagnostics, including schlieren, chemiluminescence, and planar-laser-induced fluorescence (PLIF), to name a few. To minimize the risk of damage to the quartz windows from the violent and potentially damaging combustion events, only the windows used for the optical access required by the particular optical diagnostic are installed in the vessel during flame testing. For example, the schlieren diagnostic requires two windows along a single axis, while the chemiluminescence diagnostic requires only one window. In the case of PLIF imaging, two windows on perpendicular axes are required. The unused optical access ports are instead installed with aluminum round stock, machined in-house to match the dimensions and tolerances of the windows.

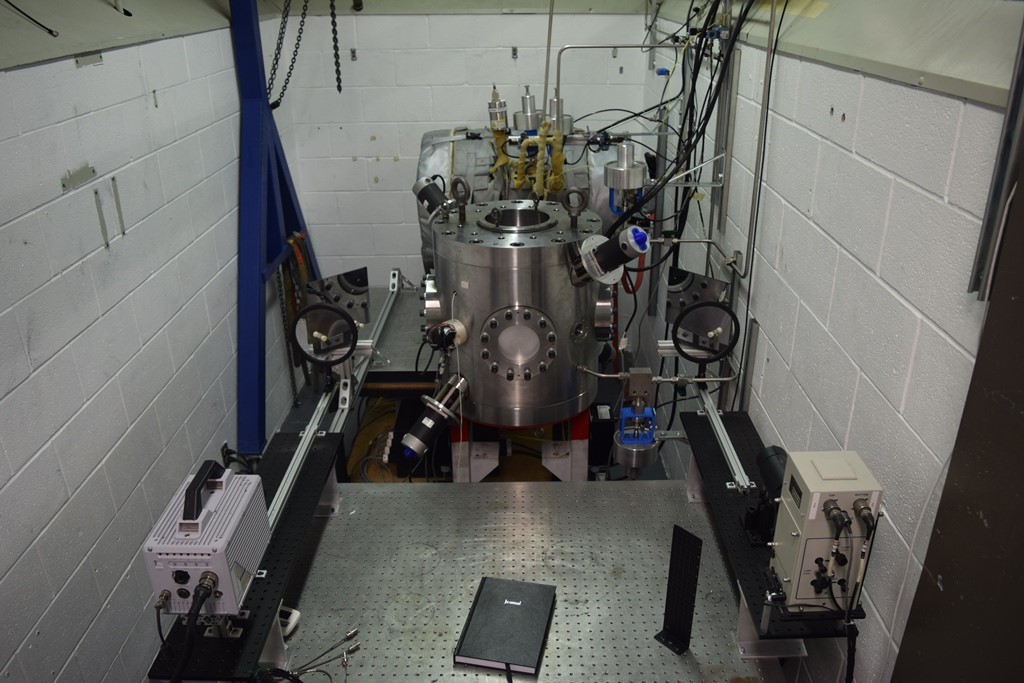

The vessel and all necessary diagnostics are located in a room built into the main combustion laboratory test cell at the the Turbomachinery Laboratory. This smaller room, known as the blast room, has cinderblock and concrete walls reinforced with steel rebar and is accessible through a locking blast door. The blast room and the main test cell are evacuated immediately prior to each flame test to ensure the safety of lab personnel in the event of a catastrophic vessel failure. In the following figure, the TFSV is shown as installed in the blast room, configured for the schlieren diagnostic. Additional information on the TFSV is detailed by Morones et al. [1, 2].

TFSV (at center) installed in the blast room in the combustion test cell at the Turbomachinery Laboratory.

References

[1] A. Morones, V. J. Leon, and E. L. Petersen, “Reconfigurable Fan-Stirred Flame Bomb with Optical Access,” 55th AIAA Aerospace Sciences Meeting, 2017, Grapevine, TX: American Institute of Aeronautics and Astronautics.

[2] A. Morones, M. A. Turner, V. J. Leon, K. Ruehle, and E. L. Petersen, “Validation of a New Turbulent Flame Speed Facility for the Study of Gas Turbine Fuel Blends at Elevated Pressure,” ASME Turbo Expo, 2019, Phoenix, AZ: American Society of Mechanical Engineers.