The propellant and energetics laboratory has developed a suite of state-of-the-art energetic safety testing capabilities to support energetic formulations development. These experiments include thermal cook-off, drop-weight impact, thermal vacuum stability, electrostatic discharge sensitivity, and thermal decomposition testing apparatuses.

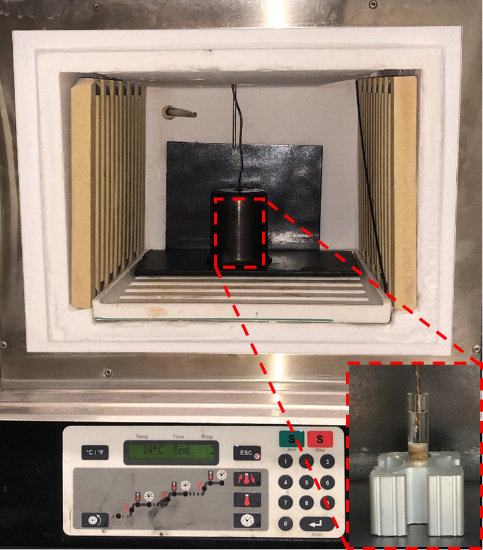

Thermal cook-off testing consists of slow heating (0.1-10 K/s) or isothermal holds (< 1000 °C) of a lab-scale (≈1 g) energetic sample in a programmable furnace. Samples can be composed of loose powder energetics, pressed pellet pyrotechnics, cured composite solid propellants, or liquid monopropellants. A representative image of a liquid monopropellant sample loaded into a Teflon-capped quartz tube for thermal cook-off testing is shown in the image below. Internal energetic temperatures are monitored with various types of thermocouples and compared to a reference thermocouple to identify exothermic and endothermic decomposition reaction temperatures.

Representative image of a thermal cook-off test containing approximately 1 gram of HAN-based liquid monopropellant.

Drop-weight impact testing is completed on an in-house impact tester capable of housing light to moderate weights (< 15 kg) at variable heights (< 1 m), yielding a range of impartible impact energies. Samples are currently restricted to solid based materials.

Vacuum thermal stability testing consists of rapid heating of an energetic sample (solid or liquid, < 100 g) to a specified temperature (< 750 C) in a chamber under vacuum (< 5 torr). The chamber was designed in house and is capable of containing a fully reacted system up to high pressure (10,000 psia) at high temperatures (750 °C). The pressure in the chamber is transiently monitored and utilized to compute the rate of gas production and thermal decomposition in the energetic sample.

In addition to the experiments developed in-house, the laboratory also has access to a wide variety of standard thermal decomposition experiments including thermal gravimetric analysis (TGA), dynamic scanning calorimetry (DSC), and dynamic thermal analysis (DTA) experimental apparatuses. Further information on these experiments is provided on the ‘Supporting Equipment and Diagnostics’ page.