Energetic gas generants are crucial components of most automotive airbag systems. Satisfactory materials for these systems must be environmentally friendly, yield a high gas output which is non-toxic and low-temperature, and minimal liquid slag. The current industry standard is composed of Guanidine Nitrate (GN) and Basic Copper Nitrate (BCN) which are environmentally friendly, readily available, and cost effective.

Improved gas generant performance can be realized by the strategic addition of additives, such as inert metal oxides, which can tailor the ballistic performance and reduce liquid slag production. Gas generant research at Texas A&M University is focused on the development of novel methods of additive synthesis and incorporation methodologies that can be utilized to further realize improved performance.

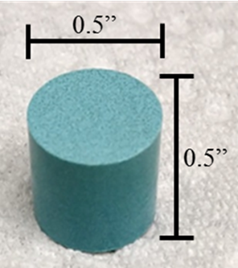

GN, BCN, and additives are homogeneously mixed though alternative methods: dry powder (Resodyn LabRAM Resonant Acoustic Mixer), wet mixing, or rotary evaporation (RE-2000B Rotary Evaporator). The mixing method can alter the dispersion of oxidizer/fuel particles or additives within the matrix and have profound effects on the resultant ballistic properties. Pellets (0.5″ 0.5″) are manufactured using a custom punch coupled with a programmable Carver M-NE3890 hydraulic press with a clamping force of up to 50,000 . Pellet specimens are burned in a constant-volume strand burner, and their burning rates, gas production, and spectral features are compared to industry standards.

Gas generant combustion at TAMU.

Gas generant sample.