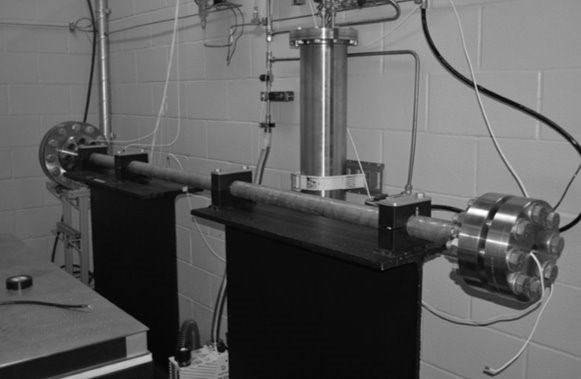

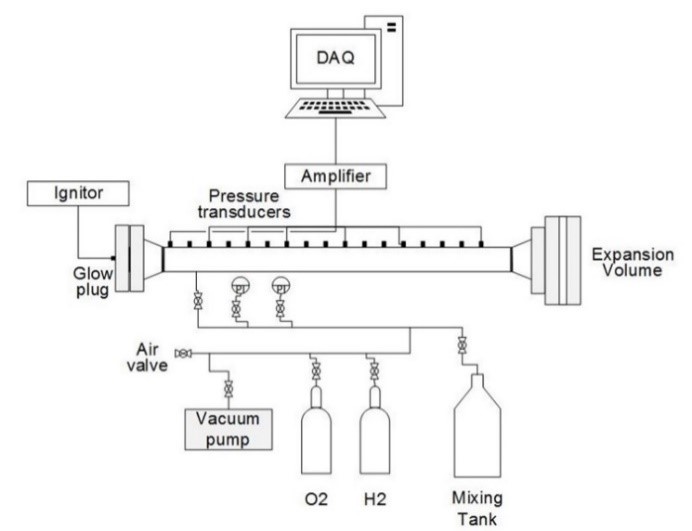

The detonation tube in our laboratory consists of a horizontal pipe with a length of 2.77 m and a 38-mm internal diameter. The tube is closed at both ends, and ignition is via a low-voltage, automotive glow plug positioned centrally at the left-endplate. An expansion volume is located at the end-wall opposed to the ignition point, and its size can be easily controlled by inserting metal plates, or “spacers”, between flange joints. During deflagration-to-detonation (DDT) tests, the expansion volume is maximized to reduce disturbances from reflected shocks propagating ahead of the flame. Seventeen (17) ports are available along the tube for flame position tracking and over-pressure readings. On-side overpressure is recorded using piezoelectric pressure transducers, PCB 113B22, with a measurement range of 34.5 MPa, a rise time smaller than 1 μs, and a resonance frequency ≥ 500 kHz. Data are recorded using a PC oscilloscope board (GaGeScope) at a sampling rate of 1 MS/s; all tests are conducted at ambient temperature, roughly 20°C, and; gaseous mixtures are prepared by the method of partial pressures in a separate mixing tank.

Image and schematic of the detonation tube at the Petersen research group