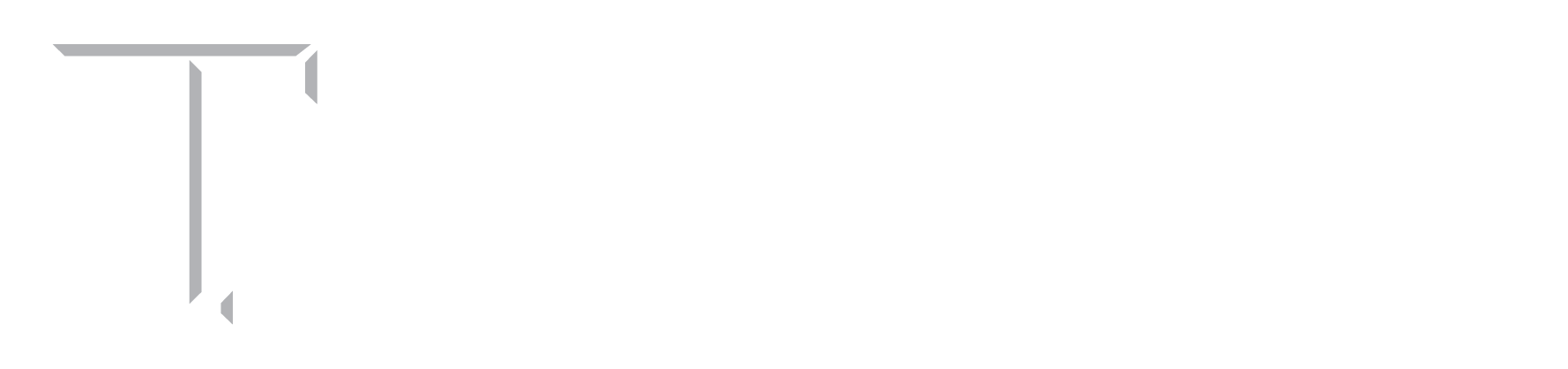

The stainless-steel, square-section shock tube at Texas A&M University is 6.1-m long with a 4-m long, 10.8-cm square driven section (2-m long, 7.6-cm i.d. round driver section). To allow for the study of low-vapor pressure fuels, the driven section and mixing tank are equipped with a custom-made heating jacket, and the manifold is wrapped with heating tape and insulation. The driven section and manifold can be heated uniformly (±2 °C) to 150 °C, and the apparatus is equipped with pressure gages auto-regulated in temperature (MKS, 0-10 and 0-1000 torr ranges). The shock-front velocity is measured using four, high-frequency piezoelectric pressure transducers (PCB 113A22) located toward the end of the shock tube with a known spacing between them. The time necessary for the shock wave to travel between two transducers is measured using 120-MHz counter/timers (Phillips P6666). Test pressure is monitored during the experiment by one PCB 134A transducer located at the endwall and one Kistler 603 B1 transducer located at the sidewall. In its classical configuration, two CaF2 windows are mounted flush with the inner wall of the reactor, in the same plane as the sidewall pressure transducer (10 mm from the endwall).

Texas A&M square shock tube with the heated jacket and optical diagnostics

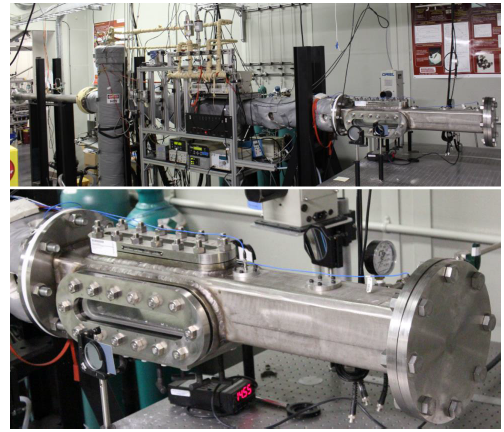

While the square section of the driver induces high-pressure limitations when performing experiments, it also allows for large, planar observation windows. For instance, a driven section extension with large windows (7.6 cm x 16.5 cm) can be used to visually monitor the shock wave dynamics in the endwall region. Another driven section extension with large windows (5.1cm x 30.5 cm) is equipped with a large dust tray with an adjustable depth (3.2 to 12.7 mm) to study dust explosions.

Texas A&M square shock tube with the dust-layer section