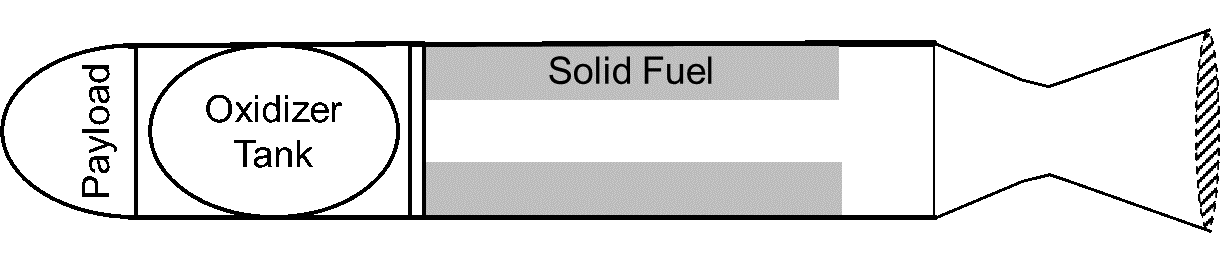

Hybrid rockets engines (HRE) differ from their pure solid or liquid counterparts in that their fuel and oxidizer are stored in separate phases (i.e. solid fuel and liquid oxidizer). A representative schematic of a hybrid rocket is shown below. Solid fuel ramjets (SFRJ) are similar to hybrid rockets, but the oxidizer is comprised of high‐velocity air captured from the atmosphere through an inlet nozzle. HREs and SFRJs are safer than traditional propulsion systems, are highly controllable, and have the potential to yield high performance; but their low solid fuel regression rates and comparatively lower combustion efficiencies have hindered their widespread adoption.

Schematic representation of ta hybrid rocket depicting the separately liquid oxidizer and solid fuel.

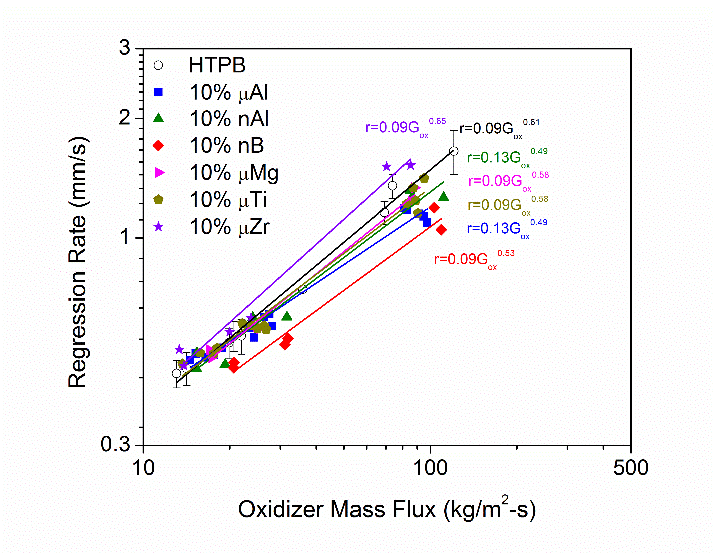

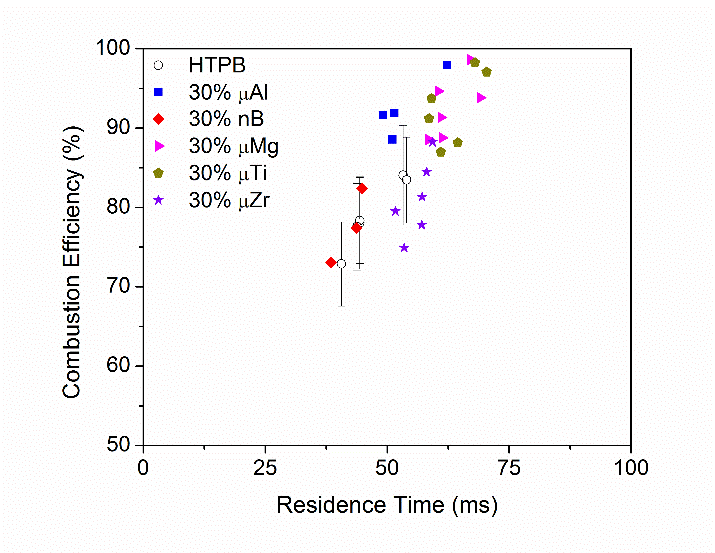

Our research has focused on the evaluation and development of metal‐based additives which can increase the volumetric energy density of these systems (Isp,v ) and yield improved ballistic performance via higher regression rates and combustion efficiencies. An example of experimental repression rates and combustion efficiencies of a solid fuel system with plain metal additives burning in gaseous oxygen (GOX) is shown below.

(left) Regression rates and (right) combustion efficiencies of metal-loaded HTPB fuel grains burning in a gaseous oxygen cross flow at a pressure of approximately 100 psia.

In conjunction with our collaborators at the University of Central Florida (Seal Research Group) and Helicon Chemical Company, we have also developed novel, energetic nano‐metal additives which do not exhibit some of the negative characteristics of traditional metal particles including reduced energy density from thick oxide layers, long ignition delay times, and low combustion efficiencies. Supporting analyses for ballistic experiments include the evaluations of the thermal decomposition, rheological, and mechanical behavior of solid-fuel systems.